Repairing the air suspension on a Case IH Engine Hour Meter can be a bit technical, but I’ll break it down into simple steps that anyone can follow with a little patience and care. Click here to view the download manual and more info…..

- Case 75c Service Overview and Detailed Service Procedures This video documents my first 300 hour service of the Cast 75c tractor.

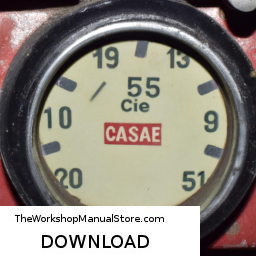

- Electrical 03 Hour Meter not working

Before starting, it’s important to gather the necessary tools and safety equipment. Here’s a step-by-step guide:

### Tools and Materials Needed:

– Basic hand tools (screwdriver, wrenches, pliers)

– Replacement parts (if necessary, such as air bags or fittings)

– air compressor (if you need to inflate the system)

– Safety goggles and gloves

### Step-by-Step Guide:

1. **Safety First**:

– Before starting any repair, make sure the equipment is turned off and is in a safe position. Wear safety goggles and gloves to protect yourself.

2. **Locate the air Suspension Components**:

– Find the air suspension system on your Case IH. This usually includes air bags, valves, and air lines. The Engine Hour Meter might not directly relate to the air suspension, but If you’re dealing with a system that monitors air pressure or has a suspension feature, it’s good to know where everything is located.

3. **Inspect for Damage**:

– Look for obvious signs of wear or damage, such as cracks in the air bags or loose air lines. If you see any air leaks (a hissing sound), that’s a sign that something needs fixing.

4. **Remove the Damaged Part**:

– If you found a damaged air bag or line, you will need to remove it. Use the appropriate tools (like wrenches or screwdrivers) to disconnect the air lines and remove the air bag. Be cautious, as there might be some residual air pressure.

5. **Install the New Part**:

– If you’re replacing an air bag or line, take the new part and install it in the same place as the old one. Make sure all connections are tight and secure to prevent leaks.

6. **Reattach air Lines**:

– Once the new part is in place, reconnect the air lines. Ensure that they are properly fitted and not kinked or pinched, as this can cause issues later.

7. **Check for Leaks**:

– After everything is connected, you can use an air compressor to fill the system. Listen carefully for any hissing sounds that indicate air leaks. If you find any, you may need to re-tighten connections or replace the parts again.

8. **Test the System**:

– With the air suspension to ensure it is functioning properly. The system should level out and respond to changes in load.

9. **Final Checks**:

– Make a final inspection of all connections and parts to ensure everything is secure. If you had to replace any parts, keep the old ones in case you need to reference them later.

10. **Documentation**:

– It’s a good practice to keep a record of any repairs or maintenance you’ve performed. This can help in the future for tracking issues or for routine maintenance checks.

### Conclusion:

While repairing air suspension can seem daunting, breaking it down into manageable steps makes the process easier. If you encounter any issues that you’re unsure about, don’t hesitate to consult a professional or refer to the Case IH service manual for guidance. Good luck with your repair!

Clear coat is a vital component in automotive paint systems, serving as the final layer applied to a vehicle’s exterior after the base color coat has been laid down. It is a transparent finish, typically made from a polymer resin, that provides a protective barrier against environmental factors such as UV rays, moisture, dirt, and contaminants. The primary purpose of the clear coat is to enhance the aesthetic appeal of the vehicle, giving it a glossy, polished appearance that accentuates the underlying color and depth of the paint.

In addition to enhancing visual appeal, clear coat plays an essential role in protecting the paint from wear and tear. It helps prevent oxidation, which can lead to fading and dullness over time. This protective layer also reduces the risk of scratches and minor abrasions, preserving the integrity of the base coat underneath. In many cases, clear coats are formulated with additional features, such as UV stabilizers, which help combat the degrading effects of sunlight.

Clear coat application is typically achieved through spray techniques, and it can be done in various thicknesses depending on the desired finish and protection. Over time, however, clear coats can degrade due to exposure to harsh elements, and may require polishing, buffing, or even reapplication to maintain their protective qualities and aesthetic appeal. Overall, clear coat is a crucial element in maintaining the longevity and appearance of a vehicle’s paint job.