Shifting the detent on a Daewoo DE12 engine involves adjusting the mechanism that allows the engine to change gears smoothly. Find additional details in the downloadable manual……

- Eltrak ????????????? ?????????????? ?????????? CAT® CCU Ba… Eltrak – ????????????? ?????????????? ?????????? CAT® ????????, ????????? ?? ?????? ??? ???????! ?? ????????????? …

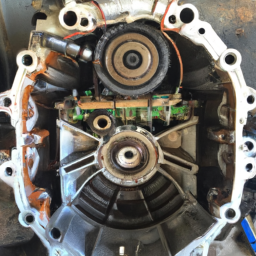

- DAEWOO DOOSAN TEREX DE12TIS ENGINE REBUILD TEST RUN http://www.sheelysupply.com DAEWOO DOOSAN TEREX DE12TIS ENGINE REBUILD TEST RUN. NEW CYLINDER BLOCK …

This process ensures that the engine operates effectively and prevents issues while driving. Here’s a step-by-step guide to help you understand how to perform a shift detent repair, keeping it simple for those with little mechanical experience:

### Tools and Materials Needed

1. **Basic Hand Tools**: Wrenches, screwdrivers, and pliers.

2. **Replacement Parts**: If necessary, replacement detent parts or springs (check your specific model).

3. **Cleaning Supplies**: Rag or cloth for cleaning.

4. **Lubricant**: Engine oil or a suitable lubricant for moving parts.

### Step-by-Step Guide

#### Step 1: Safety First

– **Ensure Safety**: Before starting any repair, make sure the engine is turned off, and the key is removed from the ignition. Let the engine cool down if it has been running.

#### Step 2: locate the Shift Detent

– **Find the Detent Mechanism**: Look for the shift detent on the side of the transmission or engine. It usually has a small lever or a rod that you can identify by tracing the gear linkage.

#### Step 3: Inspect the Detent

– **Check for Damage**: Look for any visible signs of wear, damage, or dirt. The detent should move freely without sticking. If it’s stuck, it may need cleaning or lubrication.

#### Step 4: Clean the Area

– **Remove Dirt and Debris**: Use a rag to clean around the detent area. This prevents dirt from getting into the mechanism when you work on it.

#### Step 5: Adjust or Replace the Detent

– **Adjustment**: If the detent is adjustable, use the appropriate tools to loosen the adjustment screw or nut. Move it slightly, then tighten it back up to test if the shifting improves.

– **Replacement**: If the detent is damaged and needs replacing, carefully remove it using your tools. Replace it with a new part, ensuring it fits properly. Secure it in place.

#### Step 6: Lubricate

– **Apply Lubricant**: Apply a small amount of lubricant to the moving parts of the detent. This helps ensure smooth operation when shifting gears.

#### Step 7: Test the Shift

– **Reattach Components**: If you removed any parts to access the detent, reattach them securely.

– **Start the Engine**: Turn the key to start the engine and let it run for a moment.

and let it run for a moment.

– **Test the Gears**: Shift through the gears to ensure everything is working smoothly. Check for any unusual noises or resistance.

#### Step 8: Final Check

– **Inspect Again**: After testing, do a final inspection to ensure all tools are removed, and everything is secure.

### Conclusion

Performing a shift detent repair on a Daewoo DE12 engine is a manageable task if approached step-by-step. Always prioritize safety, and don’t hesitate to consult a professional if you’re unsure about any part of the process. Regular maintenance can prevent issues and help ensure your engine runs smoothly.

An exhaust flange is a critical component in an automobile’s exhaust system, serving as a connection point between different sections of the exhaust piping. Typically made from durable materials such as steel or stainless steel, the exhaust flange is designed to withstand High temperatures and corrosive gases produced during the combustion process.

The primary function of an exhaust flange is to provide a secure and leak-proof joint between components such as the exhaust manifold, catalytic converter, muffler, and exhaust pipes. These flanges come in various shapes and sizes, and they often feature holes for bolts that allow for the secure fastening of adjoining parts. Proper installation is essential, as any gaps or leaks at the flange can lead to exhaust fumes escaping, which can be harmful to both the vehicle’s performance and the environment.

In addition to their functional role, exhaust flanges also facilitate easier maintenance and repairs. When components need to be replaced or serviced, the flanges allow for sections of the exhaust system to be disconnected without requiring the entire system to be removed. This design feature not only saves time and labor costs but also helps in maintaining the integrity of the exhaust system over time.

Overall, the exhaust flange is a vital element that plays a significant role in ensuring a vehicle’s exhaust system operates efficiently, effectively reducing emissions and maintaining engine performance. Proper care and timely replacement when worn or damaged can prevent more extensive exhaust system issues down the line.